The automotive supply chain industry has been considered mature and cost-efficient due to the history of innovative concepts from global players, which have adapted to the supply chain worldwide. However, there is always room for improvement.

Holisol, one of the country’s leading auto supply chain solution provider, backed by a founding team with over 70 years of experience, has introduced a new approach to making the automotive supply chain more effective and cost-efficient.

Three-pronged steps to make supply chain more effective

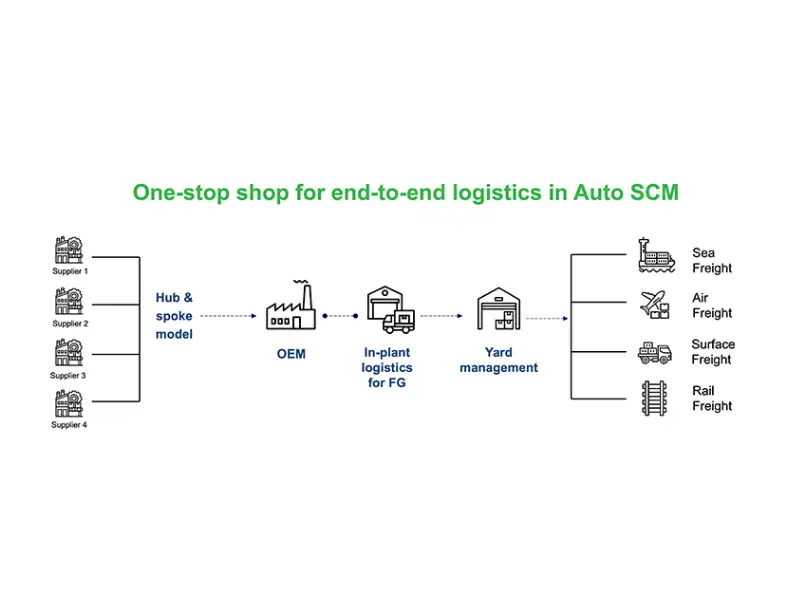

The company’s solutions for inbound and outbound parts of automated supply chain follow a 3-pronged approach:

- Increase load ability: They aim to increase load ability by allowing more products to be loaded in the same transportation unit, thereby reducing per-product transport costs.

- Reduce in-transit damages: The focus is reducing in-transit damages, which can help avoid long-term profit losses.

- Line-to-line approach: Holisol aims to make the entire supply chain seamless and more efficient through a line-to-line approach using technology, reducing the chances of error and workforce deployed to manage operations.

Advantages of Holisol Logistics solutions

Implementing these solutions reduces logistics costs by 20-30% and also helps to save carbon miles and reduce the company’s carbon footprint. However, designing these solutions requires a different mindset, engineering skills, and heavy investment in building the concepts and techniques to create and manage them.

With more than ten years of experience in this domain, the supply chain solution provider, Holisol, currently works with 25+ OEMs and 120+ OEM suppliers, providing a substantial competitive advantage over its peers in developing and deploying these solutions at a much faster speed.

Holisol’s patents and solution adoption

Over time, it has filed 35 patents, with 14 already granted, and the solutions are finding higher adoption rates for outbound shipments, where high freight costs per unit can be substantially reduced, and damages can be reduced to almost negligible levels. This brings more value to customers and helps them gain more market share in export markets.

The company is currently focused on building solutions for the PV and EV markets, with D2C EV brands set to benefit hugely from these solutions as current distribution costs can be reduced by almost 60% with their adoption.

The bottom line

Holisol’s innovative approach to the automotive supply chain is revolutionising the industry, reducing costs, and helping to reduce the carbon footprint. The company’s vast experience and extensive patent portfolio are a testament to its expertise and ability to provide tailored solutions to meet the unique needs of its customers.

About Holisol Logistics:

Holisol was founded in 2009 by Manish Ahuja, Naveen Rawat and Rahul S Dogar with a vision of empowering customers to achieve their business goals through their end-to-end supply chain management solutions. Today, it is a market leader, providing technology-enabled end-to-end supply chain logistics platforms for clients from fashion, lifestyle, beauty, personal care, e-commerce, FMCG and auto. Holisol’s solutions include omni-channel fulfillment for B2B and B2C retail. It is also an Auto supply chain Solutions provider that helps the auto sector, agriculture and the heavy engineering industry to optimise their supply chains. Its AI-ML-enabled supply chain and fulfilment tech solutions drive cost savings and efficiencies through the customer’s end-to-end supply chains.

“Our value proposition is to operate like an extended arm of a customer; we invest in understanding the customers’ supply chain, identify unfilled needs, gaps and areas of improvement and then proposed a holistic line-to-line solution to assist customer in achieving their larger business objectives.”, says Manish Ahuja, and Co-Founder & Direction of Holisol. For further information, visit https://holisollogistics.com/

Disclaimer: Content Produced by Holisol