Once thought only to exist in the realm of science fiction, 3D printers will change the world if they become popular with consumers. At present, the community is full of hobbyists and designers using their machines for smaller-scale projects. It’s impressive but only a fraction of what 3D printers can do.

Here are some of the most impressive mechanical items that have been (re)created, complete with working moving parts, entirely from scratch.

Mini Slot Machines

Many printers have created mini slot machines, from the gears inside to the colourful casing outside. Now, does this mean you’ll get a handsome pay-out if you land a winning combo? No, unless you put pocket money in there for yourself.

Printing slots would be yet another variation in a booming casino industry where patrons are spoilt for choice. While self-made prints won’t give you prizes, online slots for real cash have been around for a while and are one of the most popular ways to play. This is because online casinos offer a very wide selection of games, particularly slots, in every theme, style and ruleset.

Clocks and Watches

Before the industrial revolution kicked into gear, clockwork inventions were the height of human ingenuity. They weren’t just complex, working with many small moving parts, they looked good while doing it. Even today, we hold great value in watchmakers that make mechanical products, like Patek Philippe.

Naturally, 3D printers have tried and succeeded in reinventing mechanical clocks and watches. They’re rudimentary, and you can’t print a watch that’s worth somebody’s mortgage, but you can print a nifty timepiece for your personal enjoyment.

Mini Conveyor Belts

3D printers have also recreated one of the most impactful industrial inventions, the conveyor belt system. It’s a painstaking process to print each belt panel and join it together, so most designs are smaller as a proof of concept.

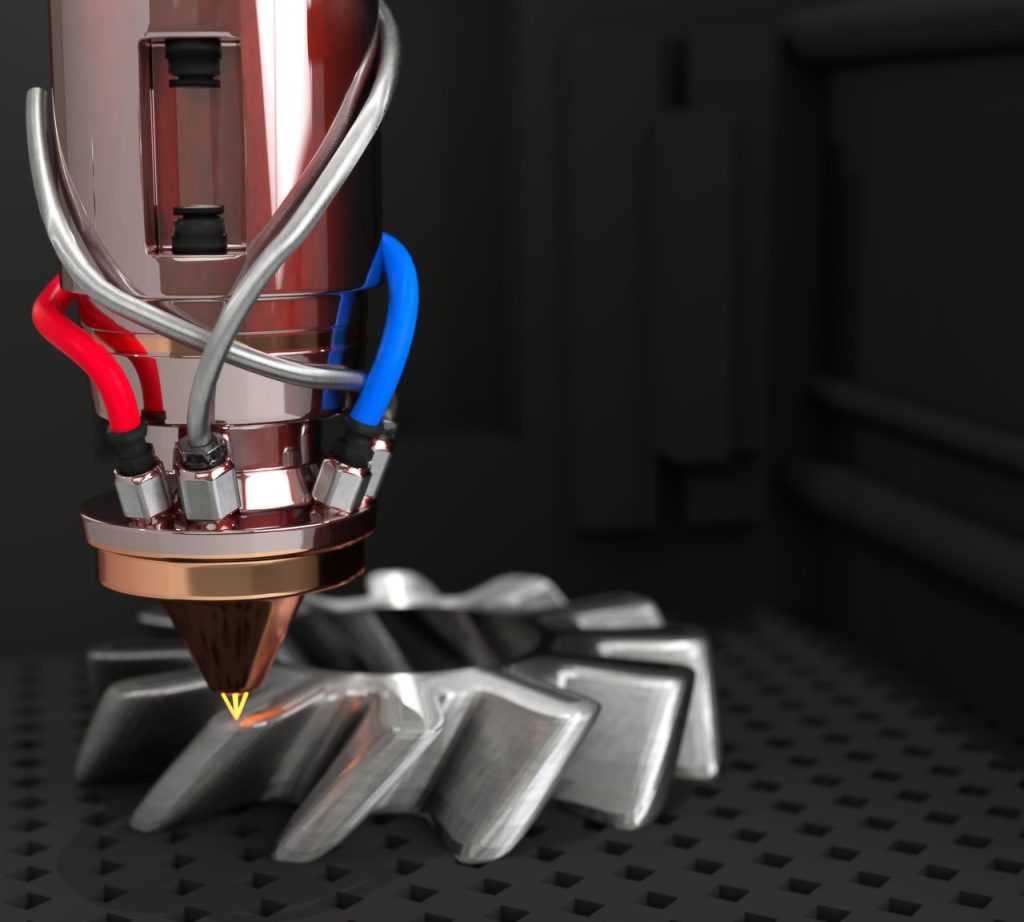

As is the case with the real thing, 3D printed conveyors are moved by a pulley system controlled by cogs and gears, all made of filament like ABS, Nylon, or metal/carbon fibre PLA variants. Metallic 3D printing is key to hardier, sophisticated print designs in the future.

While small, working models such as these show that larger conveyors could be printed in the future and benefit the industries that need them. One of the main obstacles to 3D printing adoption is the fact that most printers are small, so cannot handle larger and more complicated projects.

Conclusion

Those are some of the most technically impressive 3D prints we have seen so far, that use entirely 3D printed parts. There are many other projects that are supplemented by 3D printing and it’ll become more common as the technology improves.

As industries accept 3D printing and create larger printers, many more designs will become feasible. When we can print larger objects at-scale, and at a reduced cost to traditional manufacture, then 3D printing will take the world by storm. If that happens, these small mechanical inventions will be where it all started.